Not satisfied with training students for existing manufacturing jobs, PNW is actively working to reshape the industry to better position it for the future.

The university created the Commercialization and Manufacturing Excellence Center in 2015 to turbocharge manufacturing in the Region. The center began with two missions.

“One was to retrain people in the community around PNW that worked in the manufacturing industry who have lost their positions because of automation and robotics,” said Mont Handley, the center’s associate director. “The other side is the commercialization.”

Lately, the latter mission has taken on more importance.

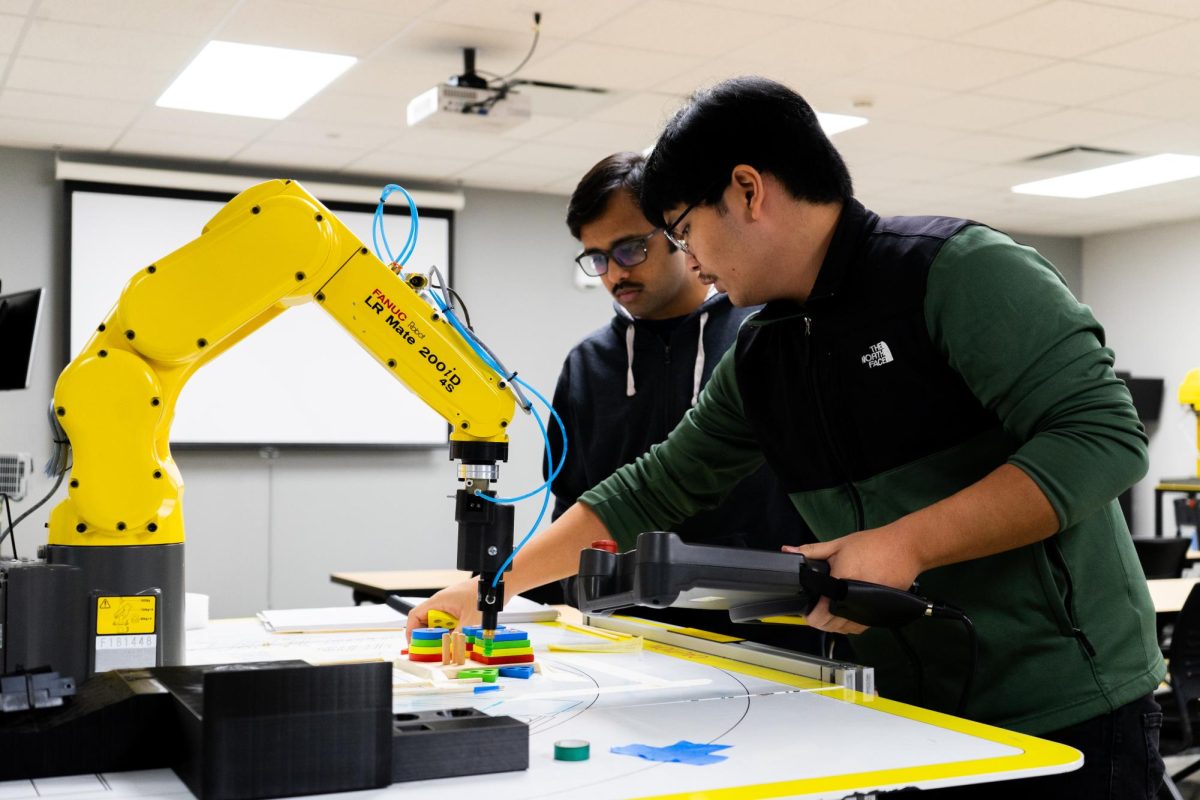

PNW CMEC provides space for faculty, students, and regional clients to innovate, create, and examine prototypes. PNW CMEC helps develop ideas for the market while training and working on technology solutions for industries through sponsored projects.

“If a student is working on a senior project and they come up with something novel, we can help them patent that … and it’s their intellectual property,” said Handley. “They could potentially build a business around that or license it.”

That is a big difference from what other schools do.

“Most universities think the intellectual property of students also belongs to the university,” he said. “I think PNW is very unique in that we’re happy to help students protect their intellectual property.”

CMEC-aided inventions are already in use. An automated dispensing machine for communion wafers was created by a client during COVID-19. Another client-created tool professionals and do-it-yourselfers can use to locate screw placements to hang the drywall.

“The CMEC building is a great place to learn and apply skills that will help students understand the technology and engineering side of STEM,” said Leonard Gonzalez, a Mechanical Engineering major. “This gives me the work experience that employers look for and can give me a bit of freedom in building products.”

Gonzalez is developing a portable electric car charger that runs on kinetic and solar energy generated while the car is driving.

“I came up with the idea from hearing concerns about people transitioning to electric vehicles and the current scarcity of chargers in certain areas across the country,” he said.

“PNW CMEC gave me a place to … build my project since I do not have access to a 3D printer to use or have space at my home to work on my project,” said Gonzalez. “Understanding common electrical components and how they work through lab experience is valuable to me and it makes me think about what I can make next or improve.”

The center supports diverse stages of commercialization, starting with concept viability assessment, in which prospective client ideas undergo evaluation. This evaluation assesses ideas technically and helps to create conceptual prototypes through 3D printers.

No idea is dismissed out of hand.

“When Google went into the market for search engines, they were 12th into the marketplace and now they dominate it,” said Handley. “It doesn’t matter if you’re first, it matters how good your invention is.”

He said CMEC helps to round out the student’s education by supplementing classroom learning with real-world experiences.

“We’re offering people with a STEM degree practical experience,” Handley said. “They work with the client directly… They develop the timeline for the project, manage the expectations, and provide the receivables to the client.

“You’re doing everything that you’re going to have to do in the workplace,” he said. “You’ve already done it, and that separates you from people who are just graduating with a degree.”